1. Introduction

Laser fusion systems such as the National Ignition Facility (NIF) require large-aperture crystals (410

![]() $\times $

410 mm) of KDP for optical switching and frequency conversion. To achieve economically useful yields, crystals grown for the NIF should exceed 53 cm in all three dimensions. The growth period of KDP crystal is about one year by the conventional lowering temperature method, which results in higher cost due to long period of growth. For this reason, new fast-growth techniques have been developed recently[Reference Loiacono, Zola and Kostescky1, Reference Zaitseva, Rashkovich and Bogatyreva2].

$\times $

410 mm) of KDP for optical switching and frequency conversion. To achieve economically useful yields, crystals grown for the NIF should exceed 53 cm in all three dimensions. The growth period of KDP crystal is about one year by the conventional lowering temperature method, which results in higher cost due to long period of growth. For this reason, new fast-growth techniques have been developed recently[Reference Loiacono, Zola and Kostescky1, Reference Zaitseva, Rashkovich and Bogatyreva2].

Conventional crystal growth uses a temperature reduction method, but the growth rate is only 1–2 mm/d, and large vessels with capacity more than 1000 l are needed for large-size crystals. The rapid growth technique has been developed greatly in recent years, and the growth rates can be more than an order of magnitude larger than those obtained with the traditional techniques. Initiated in the early 1980s by the need for large-aperture single-crystal plates in Nova and Nova’s successor, NIF, Zaitseva et al. of LLNL grew large-scale (40–55 cm) KDP crystals at rates of 10–20 mm/d, the rapid growth method is based on the use of a ‘point seed’[Reference Zaitseva, De Yoreo, Dehaven, Vital, Montgomery, Richardson and Atherton3]. Nakatsuka et al. used external energy to grow KDP crystals of 60 mm in size at high rates, in excess of 50 mm/d[Reference Nakatsuka, Fujioka, Kanabe and Fujita4]. It is shown that rapidly grown crystals can have the same high optical quality as of those typically grown by the traditional technique[Reference Bespalov, Bredikhim, Ershov, Katsman and Lavrov5, Reference De Yoreo, Rek, Zaitseva, Land and Woods6].

The ‘point seed’ in the

![]() $Z$

cutting direction, with a size of 1

$Z$

cutting direction, with a size of 1

![]() $\times $

1

$\times $

1

![]() $\times $

1 cm

$\times $

1 cm

![]() $^{{3}}$

, grows uniformly along the three directions (

$^{{3}}$

, grows uniformly along the three directions (

![]() $X$

,

$X$

,

![]() $Y$

, and

$Y$

, and

![]() $Z$

axes) under the condition of high supersaturation. The rapid crystal growth needs a higher-level stable solution without spontaneous crystallization. The level of solution stability depends on many different factors such as highly pure raw material, ultra fine filtration, overheating at high temperature, rate of temperature reduction, hydrodynamics of the crystallizer, and impurity content of solution, which actively keep the solution from spontaneous nucleation at high overcooling.

$Z$

axes) under the condition of high supersaturation. The rapid crystal growth needs a higher-level stable solution without spontaneous crystallization. The level of solution stability depends on many different factors such as highly pure raw material, ultra fine filtration, overheating at high temperature, rate of temperature reduction, hydrodynamics of the crystallizer, and impurity content of solution, which actively keep the solution from spontaneous nucleation at high overcooling.

This paper describes a successful design for a large crystallizer of a metric tonnage volume at high supersaturation; the growth parameters of a real growth process in the crystallizer are summarized. This paper reports the spectral transmittance and the laser damage threshold of the rapidly grown crystal. The optical qualities of the KDP crystals grown rapidly are not significantly different from those of KDP crystals grown by the traditional method.

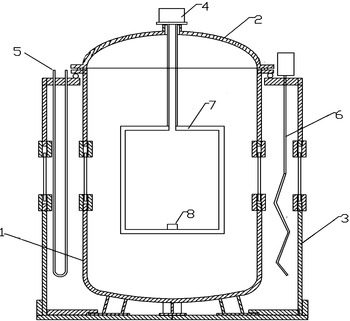

Figure 1. 2000 L crystallizer. 1-stainless steel crystallizer; 2-vessel cover; 3-thermostat; 4-rotational motor; 5-heater; 6-stirrer; 7-aluminum platform; 8-point seed.

2. Experimental

2.1. Apparatus

This experiment was carried out in a 2000 L crystallizer (Figure 1) that was placed in a water bath of temperature fluctuation less than

![]() $\pm $

0.02

$\pm $

0.02

![]() ${^\circ }$

C. The device of crystal growth can be similarly used for conventional crystal growth. The crystallizer is made from stainless steel and the inside of the crystallizer is a film of polyvinyl-fluoride of F

${^\circ }$

C. The device of crystal growth can be similarly used for conventional crystal growth. The crystallizer is made from stainless steel and the inside of the crystallizer is a film of polyvinyl-fluoride of F

![]() $_{\mathrm{46}}$

. An SYL-50 rare-earth permanent magnet DC torque motor was used to make the crystal rotation smooth and continuous. The crystal was rotated alternately in one direction and then the other on a symmetrically programmed schedule with controlled acceleration, deceleration, and rotation rates.

$_{\mathrm{46}}$

. An SYL-50 rare-earth permanent magnet DC torque motor was used to make the crystal rotation smooth and continuous. The crystal was rotated alternately in one direction and then the other on a symmetrically programmed schedule with controlled acceleration, deceleration, and rotation rates.

The acrylic or aluminum platform is of Holden type. Two brackets connect the disc plate up and down. On the centre of the platform, there is a hole, which is of suitable size for planting the crystal seed.

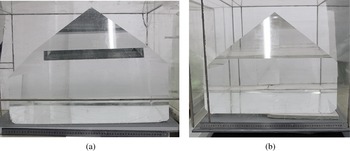

Figure 2. The grown KDP crystals with sizes of (a) 680

![]() $\times $

580

$\times $

580

![]() $\times $

540 mm

$\times $

540 mm

![]() $^{3}$

(growth period: 150 days) and (b) 650

$^{3}$

(growth period: 150 days) and (b) 650

![]() $\times $

550

$\times $

550

![]() $\times $

540 mm

$\times $

540 mm

![]() $^{3}$

(growth period: 140 days) (b).

$^{3}$

(growth period: 140 days) (b).

2.2. Crystal growth

The impurity content of KDP raw material, mainly metal ions (Fe

![]() $^{{3+}}$

, Cr

$^{{3+}}$

, Cr

![]() $^{{3+}}$

, Al

$^{{3+}}$

, Al

![]() $^{{3+}})$

, was controlled to be less than 0.1 ppm by using ultra pure product provided by a domestic manufacturer. This kind of material can reduce the width of the ‘dead zone’ [Reference Rashkovich7]. Extrapure water produced by a Milli-Q filter system with a resistivity of 18.2 M.

$^{{3+}})$

, was controlled to be less than 0.1 ppm by using ultra pure product provided by a domestic manufacturer. This kind of material can reduce the width of the ‘dead zone’ [Reference Rashkovich7]. Extrapure water produced by a Milli-Q filter system with a resistivity of 18.2 M.

![]() $\Omega \cdot \mathrm{cm}$

and was used. The temperature of the saturated solution was 60

$\Omega \cdot \mathrm{cm}$

and was used. The temperature of the saturated solution was 60

![]() $^{\circ }$

C. The solution was filtered by two filters with pore diameter of 0.22 and 0.1

$^{\circ }$

C. The solution was filtered by two filters with pore diameter of 0.22 and 0.1

![]() $\mu $

m successively. The KDP solution had been overheated at 70

$\mu $

m successively. The KDP solution had been overheated at 70

![]() $^{\circ }$

C for 24 hours. The seed was planted on the platform through a tube inserted from the top that would direct the seed into the hole after the overheating procedure. The solution temperature was lowered to 55

$^{\circ }$

C for 24 hours. The seed was planted on the platform through a tube inserted from the top that would direct the seed into the hole after the overheating procedure. The solution temperature was lowered to 55

![]() $^{\circ }$

C instantly and the point seed began to rotate at about 15 rpm and to grow in both the [001] and [100] directions. The size of the seed crystal was about 1 cubic centimeter. The overcooling was controlled between 4.5 and 5

$^{\circ }$

C instantly and the point seed began to rotate at about 15 rpm and to grow in both the [001] and [100] directions. The size of the seed crystal was about 1 cubic centimeter. The overcooling was controlled between 4.5 and 5

![]() $^{\circ }$

C. The grown crystals shown in Figure 2 are examples of successful growth. The average growth rate was between 10–15 mm/day.

$^{\circ }$

C. The grown crystals shown in Figure 2 are examples of successful growth. The average growth rate was between 10–15 mm/day.

Some crystals had no visible defects, though in many crystals solution inclusions appeared randomly on both prismatic and pyramidal faces. These defects typically were slight on the prismatic

![]() $\{100\}$

faces and much more pronounced on the top of the pyramidal

$\{100\}$

faces and much more pronounced on the top of the pyramidal

![]() $\{101\}$

faces. The nature of these defects is not yet clear and is a subject of current investigations.

$\{101\}$

faces. The nature of these defects is not yet clear and is a subject of current investigations.

3. Characterizations of KDP crystals

3.1. Optical transmission

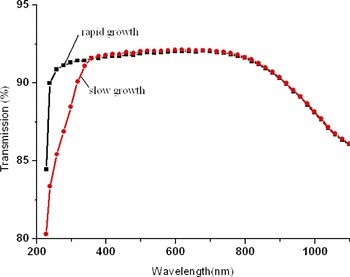

The KDP crystals grown in the experiments with a size of about 20

![]() $\times $

20

$\times $

20

![]() $\times $

10 mm were polished on the (001) faces for optical measurements. The samples of the rapidly grown crystal and the conventionally grown crystal were

$\times $

10 mm were polished on the (001) faces for optical measurements. The samples of the rapidly grown crystal and the conventionally grown crystal were

![]() $z$

-cut from the pyramidal sector. The transmission spectra, measured with a PE-lambda35 spectrometer, are shown in Figure 3. These crystals were transparent throughout both the visible and the ultraviolet (UV) regions. In the UV region, the rapidly grown KDP crystal had lower optical absorption than the KDP crystal grown by the conventional method. Additive UV absorption was found in slow-growth KDP, caused by incorporating metal-ion impurities such as Fe, Al, and Cr[Reference Land, Martin and Potapenko8].

$z$

-cut from the pyramidal sector. The transmission spectra, measured with a PE-lambda35 spectrometer, are shown in Figure 3. These crystals were transparent throughout both the visible and the ultraviolet (UV) regions. In the UV region, the rapidly grown KDP crystal had lower optical absorption than the KDP crystal grown by the conventional method. Additive UV absorption was found in slow-growth KDP, caused by incorporating metal-ion impurities such as Fe, Al, and Cr[Reference Land, Martin and Potapenko8].

3.2. Laser damage threshold

The laser damage thresholds (LDTs) were measured using well-polished

![]() $z$

-cut samples obtained in the above experiments. The measurements were carried out with a damage tester, including a Nd:YAG laser, operating at 10 Hz and pulse length 10 ns at 1064 nm. Test samples were exposed to a Gaussian beam with effective cross section of 0.79 mm

$z$

-cut samples obtained in the above experiments. The measurements were carried out with a damage tester, including a Nd:YAG laser, operating at 10 Hz and pulse length 10 ns at 1064 nm. Test samples were exposed to a Gaussian beam with effective cross section of 0.79 mm

![]() $^{{2}}$

. The damage tests are of R/1 type[Reference Burnham, Runkel and Feit9]. Table 1 shows the results of laser-induced damage threshold measurements in the prismatic and pyramidal sectors of rapidly grown KDP crystals. This standard test showed that the laser damage threshold remains at the same level in both sectors. The damage resistance meets the facility requirement.

$^{{2}}$

. The damage tests are of R/1 type[Reference Burnham, Runkel and Feit9]. Table 1 shows the results of laser-induced damage threshold measurements in the prismatic and pyramidal sectors of rapidly grown KDP crystals. This standard test showed that the laser damage threshold remains at the same level in both sectors. The damage resistance meets the facility requirement.

Table 1. Laser damage thresholds of

![]() $Z$

-cut KDP crystals.

$Z$

-cut KDP crystals.

3.3. Refractive-index nonuniformities

Efficient frequency doubling and tripling are critical for the successful operation of inertial confinement fusion laser systems. High frequency conversion efficiency is strongly dependent on attainment of the phase-matching condition. In an ideal converter crystal, one can obtain the phase-matching condition throughout by angle tuning or temperature tuning of the crystal as a whole. In real crystals, imperfections in the crystal structure prohibit the attainment of phase matching at all locations in the crystal[Reference Auerbach, Wegner and Couture10]. We have modeled frequency doubling and tripling with a quantitative measure of this departure from phase matching in real crystals, which we refer to as orthogonal polarization interferometry (OPI).

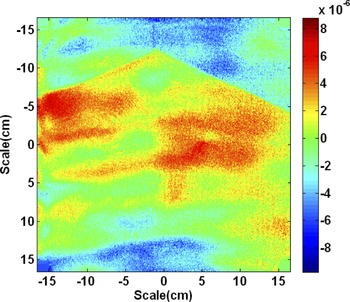

Wei et al.

[Reference Wei, Chai, Gao and Li11] used the ZYGO MST large-aperture interferometer to attain the refraction index inhomogeneity distribution of a large-size KDP crystal with precision as high as

![]() $10^{-7}$

. The diameter of the test aperture is

$10^{-7}$

. The diameter of the test aperture is

![]() $32''$

and wavelength of the used interferometer is 633 nm. The resulting

$32''$

and wavelength of the used interferometer is 633 nm. The resulting

![]() $\Delta $

(

$\Delta $

(

![]() $n_{\mathrm{e}}$

–

$n_{\mathrm{e}}$

–

![]() $n_{\mathrm{o}}$

) distribution for the rapid-growth KDP crystal is shown in Figure 4. It shows that there are two stripes on the upper part of the crystal. One slopes up from left to right, and another slopes down from right to left. The two stripes cut across each other at a midway position of the upper part, forming a boundary which represents the discontinuity of the refractive induced distribution. The sharp feature in Figure 4 is the boundary between {101} (pyramidal) and {100} (prismatic) growth regions in the rapid-growth KDP crystal. Conventional growth material is all pyramidal. The refractive-index nonuniformities existing in the rapid-growth KDP doubler will prohibit the attainment of perfect phase matching across the beam.

$n_{\mathrm{o}}$

) distribution for the rapid-growth KDP crystal is shown in Figure 4. It shows that there are two stripes on the upper part of the crystal. One slopes up from left to right, and another slopes down from right to left. The two stripes cut across each other at a midway position of the upper part, forming a boundary which represents the discontinuity of the refractive induced distribution. The sharp feature in Figure 4 is the boundary between {101} (pyramidal) and {100} (prismatic) growth regions in the rapid-growth KDP crystal. Conventional growth material is all pyramidal. The refractive-index nonuniformities existing in the rapid-growth KDP doubler will prohibit the attainment of perfect phase matching across the beam.

Figure 3. Transmission spectra of KDP crystals.

Table 2. The comparison of refractive-index nonuniformities.

Table 3. The comparison of refractive-index nonuniformities.

Figure 4. Measured

![]() $\Delta $

(

$\Delta $

(

![]() $n_{\mathrm{e}}$

–

$n_{\mathrm{e}}$

–

![]() $n_{\mathrm{o}}$

) distribution for the rapid-growth KDP doubler.

$n_{\mathrm{o}}$

) distribution for the rapid-growth KDP doubler.

We carried out third-harmonic conversion experiments on a large-scale laser facility. The crystals are 33 cm and 43 cm plates cut from a KDP boule such that the surface normal is at a specified angle relative to the crystal optical axis. The angle at which the plates are cut from the boule and oriented in the beam is chosen so as to minimize the phase mismatch factor. The result is shown in Table 2. The RMS values of rapidly grown KDP doublers are less than 1

![]() $\times $

10

$\times $

10

![]() $^{{-6}}$

. The phase mismatch factor due to the refractive-index nonuniformities in the rapid-growth KDP doubler will not lead to a remarkable reduction of the third-harmonic generation (THG) conversion efficiency at high input fundamental intensity. The property of the rapid growth KDP crystal can also meet the requirement of high conversion efficiency and good beam quality.

$^{{-6}}$

. The phase mismatch factor due to the refractive-index nonuniformities in the rapid-growth KDP doubler will not lead to a remarkable reduction of the third-harmonic generation (THG) conversion efficiency at high input fundamental intensity. The property of the rapid growth KDP crystal can also meet the requirement of high conversion efficiency and good beam quality.

3.4. Thermal conditioning

Potential thermal conditioning has been reported to increase the optically induced damage threshold[Reference Swain, Stokowski and Milam12]. As confirmation, the thermal conditioning was tested to see if it could improve the laser damage threshold of rapidly grown crystals. The same samples as used for the laser damage threshold experiment were used. An electric oven heated the samples to a temperature of 160

![]() $^{\circ }$

C, just below the destructive tetragonal/monoclinic phase transition temperature, 180

$^{\circ }$

C, just below the destructive tetragonal/monoclinic phase transition temperature, 180

![]() $^{\circ }$

C. The rising and lowering rate of temperature was 5

$^{\circ }$

C. The rising and lowering rate of temperature was 5

![]() $^{\circ }$

C/h, to prevent breaking of the samples. After baking, the refractive-index nonuniformities and the laser damage threshold were measured under the same conditions as those described above. The results of the measurement are shown in Tables 3 and 4. Thermal annealing cannot obviously improve refractive-index nonuniformities of rapidly grown KDP crystals, but thermal conditioning at 160

$^{\circ }$

C/h, to prevent breaking of the samples. After baking, the refractive-index nonuniformities and the laser damage threshold were measured under the same conditions as those described above. The results of the measurement are shown in Tables 3 and 4. Thermal annealing cannot obviously improve refractive-index nonuniformities of rapidly grown KDP crystals, but thermal conditioning at 160

![]() $^{\circ }$

C for 24 h improved the damage threshold of rapidly grown KDP crystal to 27.7 J/cm

$^{\circ }$

C for 24 h improved the damage threshold of rapidly grown KDP crystal to 27.7 J/cm

![]() $^{{2}}$

. The thermal conditioning of the rapidly grown crystals was effective in reducing the strain in the crystals and improving the laser damage threshold.

$^{{2}}$

. The thermal conditioning of the rapidly grown crystals was effective in reducing the strain in the crystals and improving the laser damage threshold.

Table 4. The comparison of damage threshold.

3.5. THG conversion efficiency

In order to study the influence of refractive-index nonuniformities on THG conversion efficiency and the near field of the third-harmonic beam, Han et al.

[Reference Han, Zhou, Wang, Li, Li, Wang, Feng, Zhu, Su and Mali13] carried out third-harmonic conversion experiments on the prototype of the SG-III laser facility which can deliver 2.4 kJ per beam at a wavelength of 1053 nm with a narrow bandwidth, a 1 ns pulse duration, and a 29 cm

![]() $\times $

29 cm beam size. The fundamental beam from the main amplifier of the prototype was delivered into the final optical assembly, which consists of a vacuum window, a frequency converter consisting of a KDP doubler and a KDP tripler, and a fused silica focusing lens. The THG configuration we used in the experiment is an 11 mm thick type I rapid growth KDP doubler followed by a 9 mm thick type II traditional growth KDP tripler. The aperture of both crystals was 330 mm

$\times $

29 cm beam size. The fundamental beam from the main amplifier of the prototype was delivered into the final optical assembly, which consists of a vacuum window, a frequency converter consisting of a KDP doubler and a KDP tripler, and a fused silica focusing lens. The THG configuration we used in the experiment is an 11 mm thick type I rapid growth KDP doubler followed by a 9 mm thick type II traditional growth KDP tripler. The aperture of both crystals was 330 mm

![]() $\times $

330 mm. After the target, a sampling mirror was used for third-harmonic beam energy and nearfield measurements. A self-made MSC-type energy meter was used to determine the efficiency with sensitivity of 10

$\times $

330 mm. After the target, a sampling mirror was used for third-harmonic beam energy and nearfield measurements. A self-made MSC-type energy meter was used to determine the efficiency with sensitivity of 10

![]() $\mu $

v/mJ and measuring energy range 200 mJ–20 J.

$\mu $

v/mJ and measuring energy range 200 mJ–20 J.

The highest conversion efficiencies at the input fundamental intensities of 1.2 GW/cm

![]() $^{{2}}$

and 2.5 GW/cm

$^{{2}}$

and 2.5 GW/cm

![]() $^{{2}}$

are 58.7% and 58.4%, respectively. In the experiment, the optimum detuning angle of the doubler is about 130 rad, smaller than the theoretical value. This is because other factors, such as the fundamental beam wavefront, refractive-index nonuniformities, surface figure of the doubler, and so on, reduced the doubling efficiency. The phase mismatch factor due to the refractive-index nonuniformities in rapid-growth KDP doubler will not lead to a remarkable reduction of the THG conversion efficiency at high input fundamental intensity.

$^{{2}}$

are 58.7% and 58.4%, respectively. In the experiment, the optimum detuning angle of the doubler is about 130 rad, smaller than the theoretical value. This is because other factors, such as the fundamental beam wavefront, refractive-index nonuniformities, surface figure of the doubler, and so on, reduced the doubling efficiency. The phase mismatch factor due to the refractive-index nonuniformities in rapid-growth KDP doubler will not lead to a remarkable reduction of the THG conversion efficiency at high input fundamental intensity.

4. Conclusions

The result obtained from the present work was on the basis of the development of the rapid-growth technique. Our results show that large KDP single crystals for laser fusion systems can be grown rapidly using high supersaturations. In our experiments we managed to accelerate the KDP crystal growth rate by aggrandizing the supersaturation of the KDP solution, improving the purity of the KDP solution, and making the KDP crystal rotation reasonable. We have successfully grown a KDP crystal with a size of 680

![]() $\times $

580

$\times $

580

![]() $\times $

540 mm

$\times $

540 mm

![]() $^{3}$

at an average rapid-growth rate of 10 mm/day without a complicated continuous filtration system. The optical quality of the KDP crystals was characterized. We have developed a stable technique for obtaining KDP up to 60 cm in size having high optical quality including a high laser damage threshold.

$^{3}$

at an average rapid-growth rate of 10 mm/day without a complicated continuous filtration system. The optical quality of the KDP crystals was characterized. We have developed a stable technique for obtaining KDP up to 60 cm in size having high optical quality including a high laser damage threshold.

According to the experimental results, the impact of refractive-index nonuniformities on the THG conversion efficiency can be deemed acceptable, but efforts should be made to eliminate refractive index discontinuities in rapid-growth KDP crystals.

Acknowledgements

This work was performed under the auspices of the State High Technology Program for Inertial Confinement Fusion, which is gratefully acknowledged.