Abstract

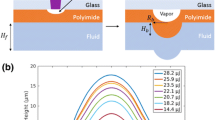

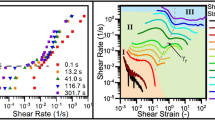

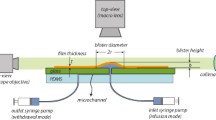

Blister-actuated laser-induced forward transfer (BA-LIFT) is a direct-write technique, which enables high-resolution printing of sensitive inks for electronic or biological applications. During BA-LIFT, a polymer laser-absorbing layer deforms into an enclosed blister and ejects ink from an adjacent donor film. In this work, we develop a finite element model to replicate and predict blister expansion dynamics during BA-LIFT. Model inputs consist of standard mechanical properties, strain-rate-dependent material parameters, and a parameter encapsulating the thermal and optical properties of the film. We present methods to determine these material parameters from experimental measurements. The simulated expansion dynamics are shown to be in good agreement with experimental measurements using two different polymer layer thicknesses. Finally, the ability to model high-fluence blister rupture is demonstrated through a strain-based failure approach.

Similar content being viewed by others

References

J. Bohandy, B.F. Kim, and F.J. Adrian: Metal deposition from a supported metal film using an excimer laser. J. Appl. Phys. 60, 1538 (1986).

A. Piqué, D.B. Chrisey, R.C.Y Auyeung, J. Fitz-Gerald, H.D. Wu, R.A. McGill, S. Lakeou, P.K. Wu, V. Nguyen, and M. Duignan: A novel laser transfer process for direct writing of electronic and sensor materials. Appl. Phys. A 69, 279 (1999).

A. Piqué, C.B. Arnold, H. Kim, M. Ollinger, and T.E. Sutto: Rapid prototyping of micropower sources by laser direct-write. Appl. Phys. A 79, 783 (2004).

C.B. Arnold, P. Serra, and A. Piqué: Laser direct-write techniques for printing of complex materials. MRS Bull. 32, 23 (2007).

D.A. Willis, and V. Grosu: Microdroplet deposition by laser-induced forward transfer. Appl. Phys. Lett. 86, 244103–1 (2005).

V. Schultze and M. Wagner: Blow-off of aluminium films. Appl. Phys., A Solids Surf. 53, 241 (1991).

M. Colina, M. Duocastella, J.M. Fernández-Pradas, P. Serra, and J.L. Morenza: Laser-induced forward transfer of liquids: Study of the droplet ejection process. J. Appl. Phys. 99, 084909–1 (2006).

M. Colina, P. Serra, J.M. Fernández-Pradas, L. Sevilla, and J.L. Morenza: DNA deposition through laser induced forward transfer. Biosens. Bioelectron. 20, 1638 (2005).

J.M. Fitz-Gerald, A. Piqué, D.B. Chrisey, P.D. Rack, M. Zeleznik, R.C.Y Auyeung, and S. Lakeou: Laser direct writing of phosphor screens for high-definition displays. Appl. Phys. Lett. 76, 1386 (2000).

M. Brown, N. Kattamis, and C. Arnold: Time-resolved dynamics of laser-induced micro-jets from thin liquid films. Microfluid. Nanofluid. 11, 199 (2011).

N.T. Kattamis, N.D. McDaniel, S. Bernhard, and C.B. Arnold: Laser direct write printing of sensitive and robust light emitting organic molecules. Appl. Phys. Lett. 94, 103306–1 (2009).

R. Fardel, M. Nagel, F. Nüesch, T. Lippert, and A. Wokaun: Fabrication of organic light-emitting diode pixels by laser-assisted forward transfer. Appl. Phys. Lett. 91, 061103–1 (2007).

J. Xu, J. Liu, D. Cui, M. Gerhold, A.Y. Wang, M. Nagel, and T.K. Lippert: Laser-assisted forward transfer of multi-spectral nanocrystal quantum dot emitters. Nanotechnology 18, 025403–1 (2007).

S.H. Ko, H. Pan, S.G. Ryu, N. Misra, C.P. Grigoropoulos, and H.K. Park: Nanomaterial enabled laser transfer for organic light emitting material direct writing. Appl. Phys. Lett. 93, 151110–1 (2008).

A.J. Birnbaum, K. Heungsoo, N.A. Charipar, and A. Piqué: Laser printing of multi-layered polymer/metal heterostructures for electronic and MEMS devices. Appl. Phys. A 99, 711 (2010).

M.S. Brown, N.T. Kattamis, and C.B. Arnold: Time-resolved study of polyimide absorption layers for blister-actuated laser-induced forward transfer. J. Appl. Phys. 107, 083103–1 (2010).

N.T. Kattamis, P.E. Purnick, R. Weiss, and C.B. Arnold: Thick film laser induced forward transfer for deposition of thermally and mechanically sensitive materials. Appl. Phys. Lett. 91, 171120–1 (2007).

N.T. Kattamis, N.D. McDaniel, S. Bernhard, and C.B. Arnold: Ambient laser direct-write printing of a patterned organo-metallic electroluminescent device. Org. Electron. 12, 7 (2011).

S. Moaveni: Finite Element Analysis: Theory and Application with Ansys, 3rd ed. (Prentice Hall, Upper Saddle River, NJ, 2007).

Dupont, Kapton Polyimide Film Product Information, p. 3.

A. Mostofi: The incorporation of damping in lumped-parameter modelling techniques: Proceedings of the Institution of Mechanical Engineers, Part K. J. Multi-Body Dynam. 213, 11 (1999).

G.B. Warburton: The Dynamic Behaviour of Structures, 2nd ed. (Pergamon Press, Oxford/New York, 1976).

E.L. Wilson and J. Penzien: Evaluation of orthogonal damping matrices. Int. J. Numer. Methods Eng. 4, 5 (1972).

J.F. Hall: Problems encountered from the use (or misuse) of Rayleigh damping. Earthquake Eng. Struct. Dynam. 35, 525 (2006).

J.H. Brannon, J.R. Lankard, A.I. Baise, F. Burns, and J. Kaufman: Excimer laser etching of polyimide. J. Appl. Phys. 58, 2036 (1985).

S. Küper, J. Brannon, and K. Brannon: Threshold behavior in polyimide photoablation: Single-shot rate measurements and surface-temperature modeling. Appl. Phys., A Solids Surf. 56, 43 (1993).

D.C. Drucker and W. Prager: Soil mechanics and plastic analysis for limit design. Q. Appl. Math. 10, 157 (1952).

D. Peirce, C.F. Shih, and A. Needleman: A tangent modulus method for rate dependent solids. Comput. Struct. 18, 875 (1984).

R. Krüger, M. König, and T. Schneider: Computation of local energy release rates along straight and curved delamination fronts of unidirectionally laminated DCB and ENF specimens, in Proceedings of the 34th AIAA/ASME/ASCE/AHS/ASC SSDM Conference, 1332 (1993).

T.K. Hellen: On the method of virtual crack extensions. Int. J. Numer. Methods Eng. 9, 187 (1975).

D.M. Parks: The virtual crack extension method for nonlinear material behavior. Comput. Meth. Appl. Mech. Eng. 12, 353 (1977).

F.Z. Li, C.F. Shih, and A. Needleman: A comparison of methods for calculating energy release rates. Eng. Fract. Mech. 21, 405 (1985).

B. Moran and C.F. Shih: Crack tip and associated domain integrals from momentum and energy balance. Eng. Fract. Mech. 27, 615 (1987).

E.F. Rybicki and M.F. Kanninen: A finite element calculation of stress intensity factors by a modified crack closure integral. Eng. Fract. Mech. 9, 931 (1977).

K.N. Shivakumar, P.W. Tan, and J.C. Newman Jr.: A virtual crack-closure technique for calculating stress intensity factors for cracked three dimensional bodies. Int. J. Fract. 36, R43 (1988).

R. Krueger: Virtual crack closure technique: History, approach, and applications. Appl. Mech. Rev. 57, 109 (2004).

L.P. Buchwalter and R.H. Lacombe: Adhesion of polyimide to fluorine-contaminated SiO2 surface. Effect of aminopropyltriethoxysilane on the adhesion. J. Adhes. Sci. Technol. 5, 449 (1991).

L.P. Buchwalter, T.S. Oh, and J. Kim: Adhesion of polyimides to ceramics. Effects of aminopropyltriethoxysilane and temperature and humidity exposure on adhesion. J. Adhes. Sci. Technol. 5, 333 (1991).

K.L. Mittal: Adhesion Measurement of Films and Coatings: Relative Adhesion Measurement for Thin Film Microelectronic Structures. Part II, Vol. 2 (VSP, Boston, 2001), p. 26.

W.D. Calister: Material Science and Engineering: An Introduction, 7th edition. (Wiley, New York, 2007).

R.W. Hertzberg: Deformation and Fracture Mechanisms of Engineering Materials, 4th ed. (John Wiley & Sons, Inc., New York, 1996), p. 225.

A.S. Argon: Theory for the low-temperature plastic deformation of glassy polymers. Philos. Mag. 28, 839 (1973).

M.C. Boyce, D.M. Parks, and A.S. Argon: Large inelastic deformation of glassy polymers. part I: Rate dependent constitutive model. Mech. Mater. 7, 15 (1988).

J.E. Field, S.M. Walley, W.G. Proud, H.T. Goldrein, and C.R. Siviour: Review of experimental techniques for high rate deformation and shock studies. Int. J. Impact Eng. 30, 725 (2004).

E.O.W.J Harding and J.D. Campbell: Tensile testing of materials at high impact rates of strain. J. Mech. Eng. Sci. 2, 88 (1960).

B.A. Hopkinson: A method of measuring the pressure produced in the detonation of high explosives or by the impact of bullets. Philos. Trans. R. Soc. London, Ser. A 213, 437 (1914).

G.T. Gray: ASM Handbook Mechanical Testing and Evaluation: Shock Wave Testing of Ductile Materials, Vol. 8 (ASM International, Materials Park, OH, 2000), p. 530.

P. Perzyna: Advances in Applied Mechanics: Fundamental Problems in Viscoplasticity, Vol. 9 (Academic Press, New York, 1966), p. 243.

R. Fabbro, J. Fournier, P. Ballard, D. Devaux, and J. Virmont: Physical study of laser-produced plasma in confined geometry. J. Appl. Phys. 68, 775 (1990).

G. Paraskevopoulos, D.L. Singleton, R.S. Irwin, and R.S. Taylor: Time-resolved reflectivity as a probe of the dynamics of laser ablation of organic polymers. J. Appl. Phys. 70, 1938 (1991).

M.N. Ediger and G.H. Pettit: Time-resolved reflectivity of ArF laser-irradiated polyimide. J. Appl. Phys. 71, 3510 (1992).

D.L. Singleton, G. Paraskevopoulos, and R.S. Taylor: Dynamics of excimer laser ablation of polyimide determined by time-resolved reflectivity. Appl. Phys., B Photophys. Laser Chem. 50, 227 (1990).

G.H. Pettit, M.N. Ediger, D.W. Hahn, B.E. Brinson, and R. Sauerbrey: Transmission of polyimide during pulsed ultraviolet laser irradiation. Appl. Phys., A Solids Surf. 58, 573 (1994).

H. Schmidt, J. Ihlemann, B. Wolff-Rottke, K. Luther, and J. Troe: Ultraviolet laser ablation of polymers: Spot size, pulse duration, and plume attenuation effects explained. J. Appl. Phys. 83, 5458 (1998).

G. Koren: Temporal measurements of photofragment attenuation at 248 nm in the laser ablation of polyimide in air. Appl. Phys. Lett. 50, 1030 (1987).

A.F. Bower: Applied Mechanics of Solids (CRC Press, New York, 2010), p. 553.

Acknowledgments

This work was supported by the National Science Foundation (MRSEC Program) through the Princeton Center for Complex Materials (DMR 0819860), the National Science Foundation (DMR-0548147), and the Air Force Office of Scientific Research (AFOSR-FA9550-08-1-0094).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kattamis, N.T., Brown, M.S. & Arnold, C.B. Finite element analysis of blister formation in laser-induced forward transfer. Journal of Materials Research 26, 2438–2449 (2011). https://doi.org/10.1557/jmr.2011.215

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2011.215